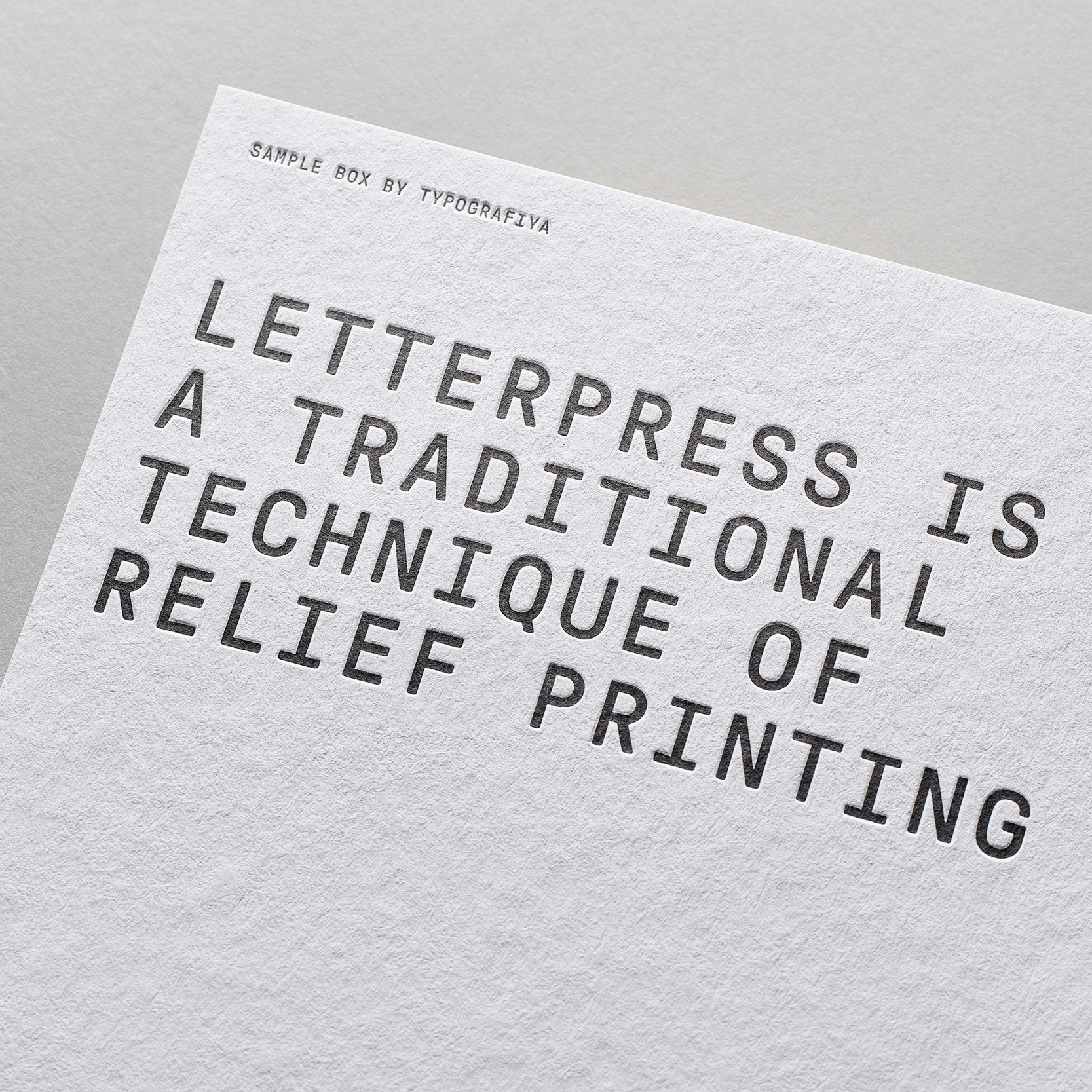

Letterpress

This is a traditional technique of hand printing. Transferring ink to bulk paper along with a relief impression using a polymer plate. The unique tactile and visual effect of relief printing is accomplished on cotton paper.

Transferring ink to bulk paper along with a relief impression using a polymer mold.

1. Letterpress means a relief impression. The ink is pressed into the paper. The maximum relief is obtained on low-bold elements (line thickness 0.2-3 mm) and the density of cotton paper is 500-700 gsm.

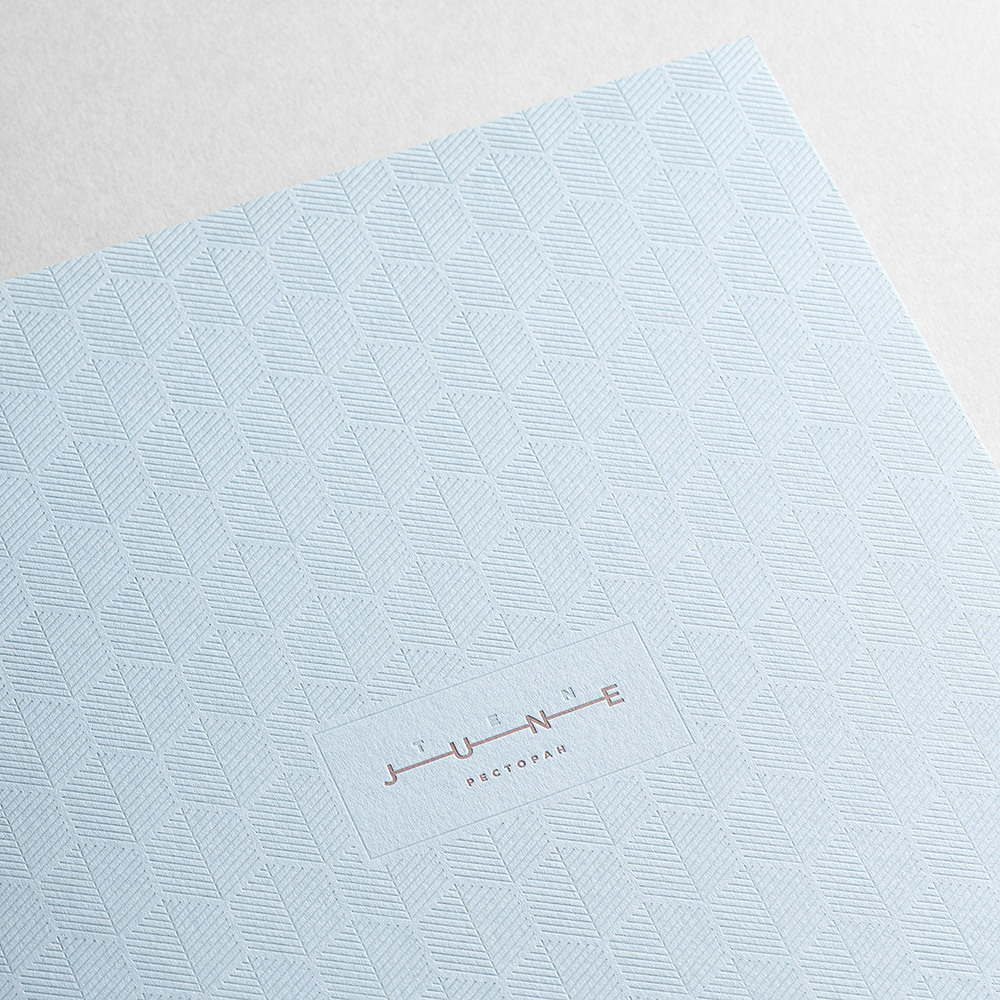

2. Only on light paper. Ink for the letterpress is translucent, so the color of the ink should be darker than the color of the paper. On white or light gray paper, printing is possible in any color. And, for example, on red paper — only in black. The exception is metallic ink (gold or silver). Metallic ink covers dark or black paper. But they look less intense than silk screen printing or foil stamping.

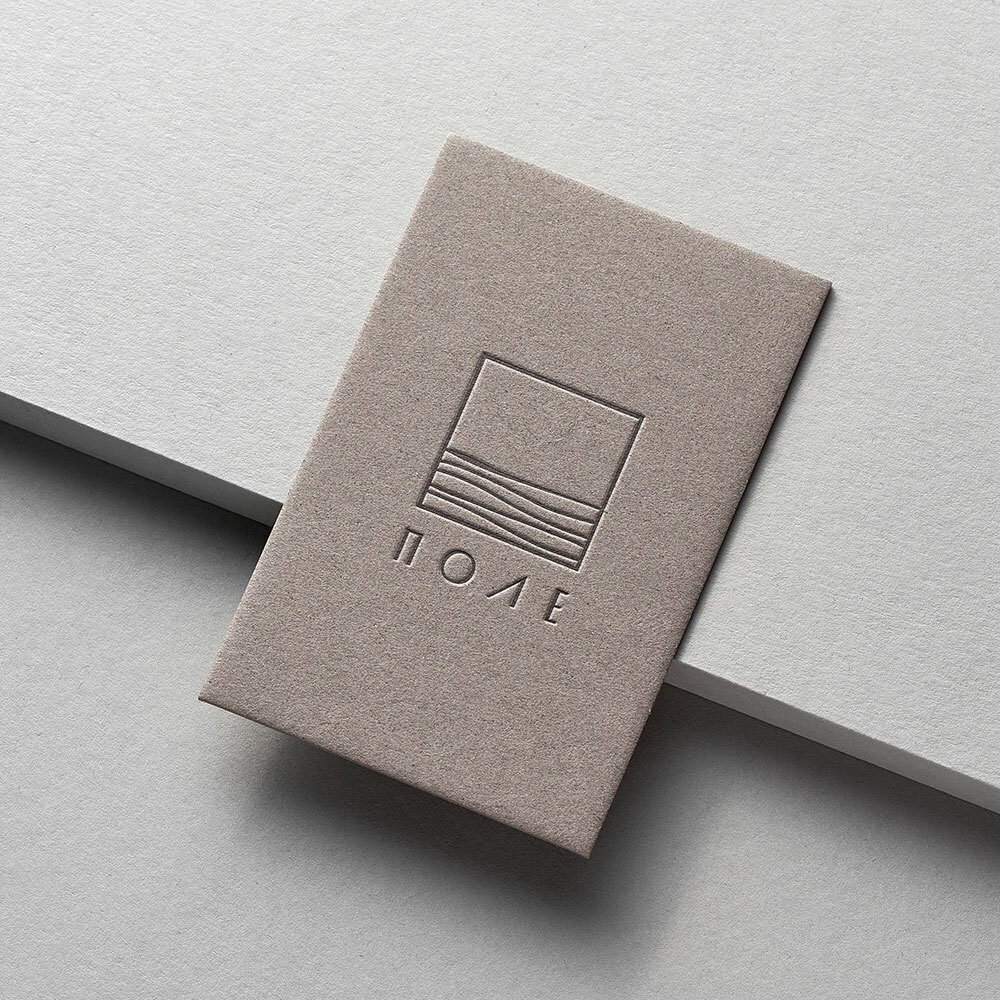

3. The high-density cotton paper (500-700 gsm) is recommended for letterpress printing. It is also possible to print on other types of uncoated paper, but the relief is much weaker. Only black, gold, or silver ink can be printed on coloured paper, blind embossing is also possible. Synthetic coated paper is not suitable for letterpress.

4. No big fills. Do not use large fills in your layout for letterpress. Otherwise, the printed area will be uneven and the relief will be hardly noticeable.

5. Matte ink. Matte ink is used for letterpress and absorbed into the paper. The ink color is selected according to the Pantone Uncoated palette (for uncoated paper). Ink looks less intense than on glossy paper. If you need an exact Pantone color, you must specify it in your order. Otherwise, color claims will not be accepted.

6. The minimum line thickness is 0.15 mm

Paper options:

— Cotton

— Coloured paper (only blind impression or silver/golden/black ink)

— Embossed paper (only light tones, small relief)