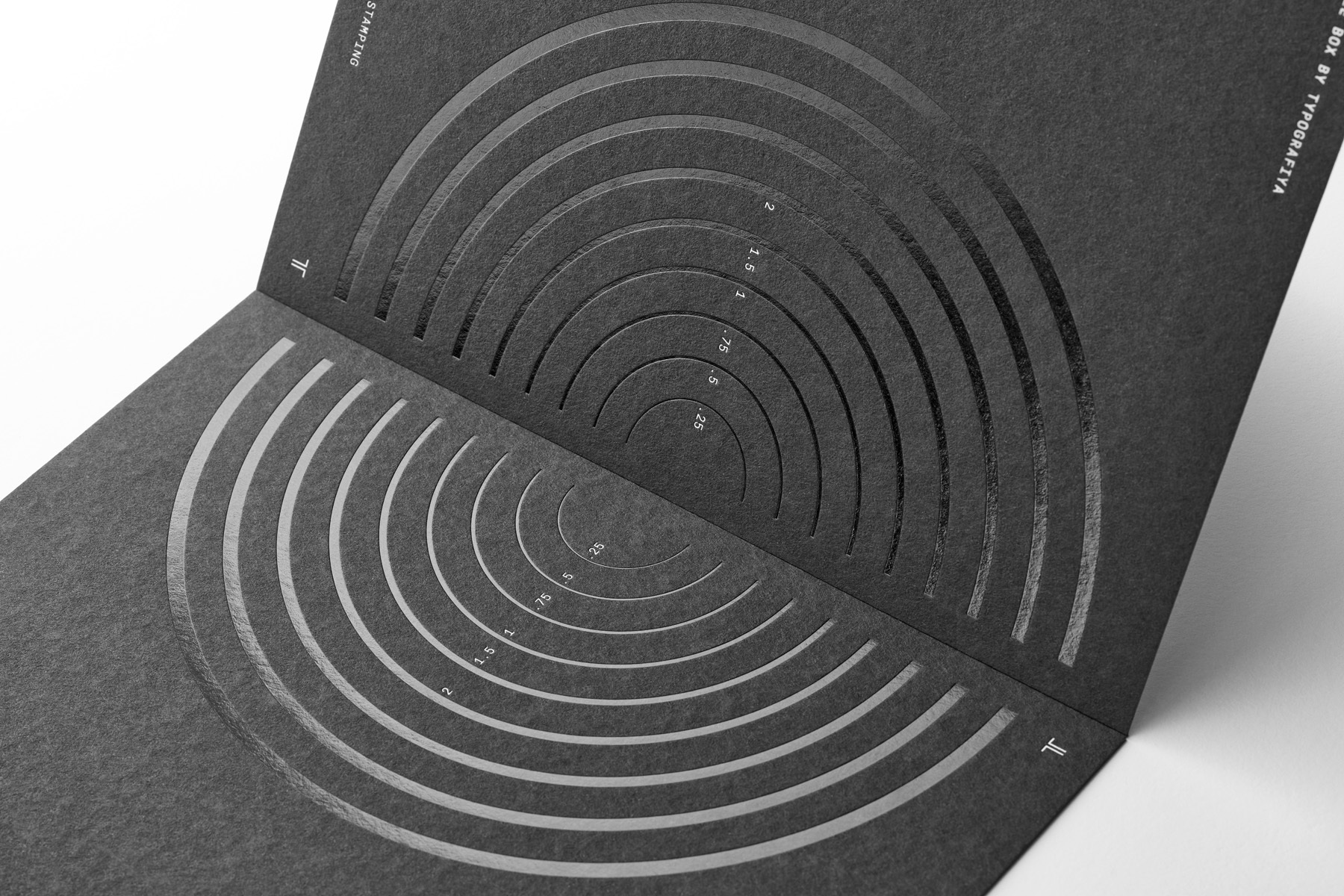

Foil Stamping

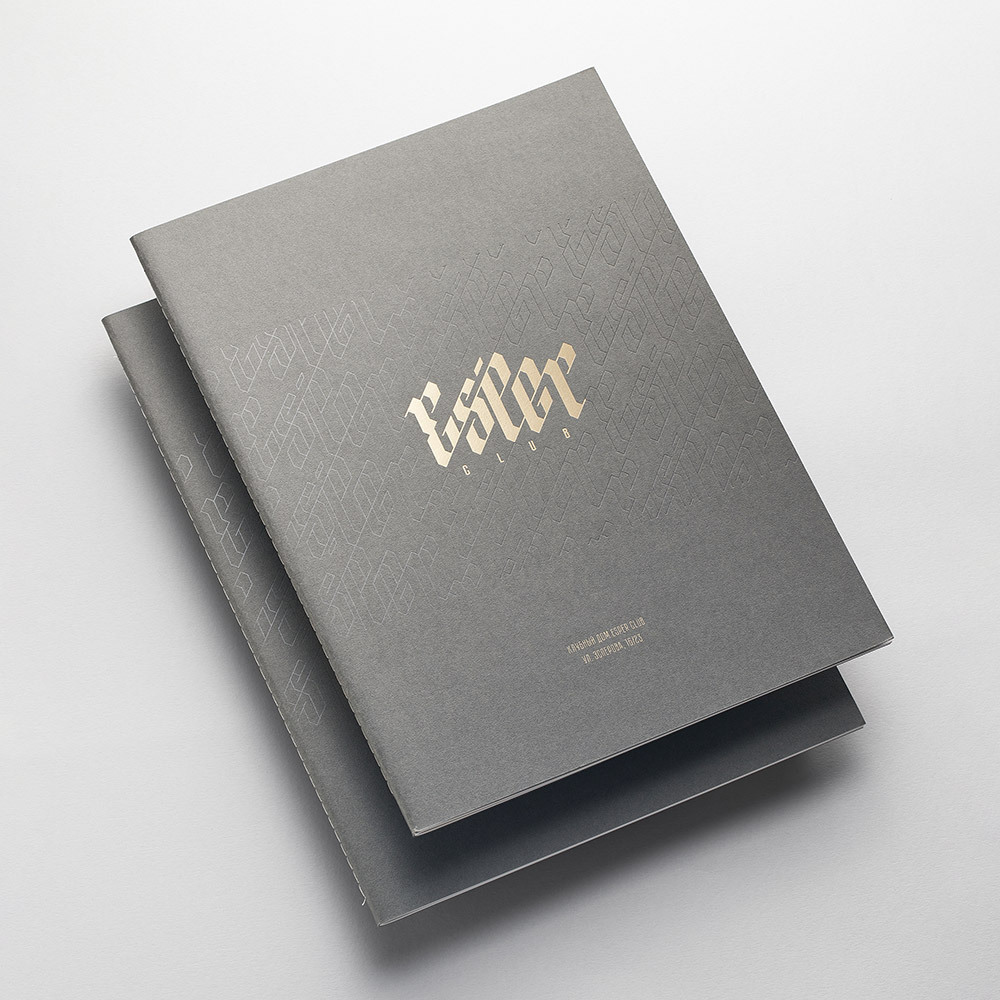

An application of foil along with the print impression by applying a heated die onto the foil. The foil stamping elements acquire the characteristic metallic glow. Foil stamping will add your product a premium character.

An application of foil along with the print impression by applying a heated die onto the foil.

1. Foil stamping elements acquire a metallic luster.

2. Foil stamping elements are slightly pressed into the paper, but not as deep as letterpress.

3. To reach the greatest clarity, it is necessary to choose smooth and smooth paper. Foil stamping looks less clear on cotton paper due to its bulk.

4. Foil is divided into classic metallic shades (gold, silver, copper) and other colors. You should better specify the existence of exclusive colors. Available foil colors can be viewed here. Foil can be matte and glossy. Matte foil always looks sharper at the edges of images and clearer on textured and rough surfaces.

5. The minimum line thickness for foil stamping is 0.2 mm. Large solid areas should be avoided. Their presence should be warned before order and consulted about the possibility of printing.

Paper options:

— Design cardboard

— Tactile paper

— Cotton